Do you use lease haulers or sub-contractors? How do you get them to sign your contract, and provide company and insurance information? If you do this like most companies, you ...

While the economy may be booming with lots of new construction, it is important to keep an eye on your numbers to ensure that you are maximizing your profits. If the influx of new business is stretching your dump truck service company to the limits, now may be the time to look at implementing new processes to improve your efficiency and your profits.

Many people think they can create a quote faster by using a calculator and paper or email instead of using quoting software. However, there are several things they are not taking into account. The manual and email processes have more room for error and inconsistent pricing. Later this person spends a lot of time searching for the paper proposal or the document in an email.

While some businesses in the construction industry have a software program for creating bids and estimates, few have a system that is integrated with order processing and dispatching.

What happens when the person doing the dispatching is not the same person who created the proposal? Does the dispatcher even know that there is a quote, or will they end up pricing this again when creating and scheduling the order? This makes customers unhappy when the price changes or they have to wait for another quote to be created.

A good order and dispatch software system will streamline this flow so that when a proposal is created for a customer, it can be used to create the order. Cloud-based software allows salespeople in the field to enter a quote and for it to be immediately available to the dispatcher.

A streamlined, integrated software application reduces the communications between the salesperson and the dispatcher. Searching for quotes and orders takes seconds instead of minutes. In the manual system, when a paper quote can’t be found within 5 or 10 minutes, it normally gets handwritten onto another sheet of paper, resulting in duplicate effort.

Many dump truck service companies are still working with paper orders. Are you one of them? If so, how do you ensure that you have all the pieces of paper representing today’s or tomorrow’s orders? Did you remember the order placed last month, or the ones created the day the substitute dispatcher was working?

Even if you have all the orders in hand, how do you plan the order of the deliveries? If something changes, how difficult is it to juggle the remaining orders? Often, this results in much chaos around the dispatch office. Inability to schedule and dispatch trucks accurately and timely results in drivers working over time or missed orders and unhappy customers.

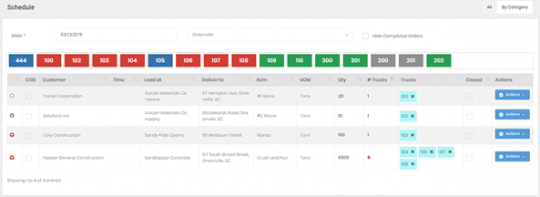

Think of how much smoother dispatching would go if you had software that allowed you to schedule your orders in advance and to assign the trucks to deliveries. Good planning and dispatching software is very visual and lets you see the availability of your trucks at a glance. It will also let you readily see which orders have not yet been scheduled.

What happens if your main dispatcher is sick or quits? The paper-based system will be much harder for the new dispatcher to pick up the pieces. With a good software application, all the data will be available, and the system will enforce a good, repeatable process. You don’t have to worry about all the information being in the old dispatcher’s head.

An example of a system that allows you to schedule your orders might look like the below. Note how the trucks shown in the top section change color. Green trucks have availability and red trucks are fully utilized. In the “# of Trucks” column, note the 2 red numbers indicating that not enough trucks have been scheduled.

There is an extensive amount of logic built into the scheduling and dispatching functionality to keep your dispatcher out of trouble.

Do you have trouble collecting and reconciling all the tickets to a job? Are your drivers and sub-contractors slow to turn in the tickets so that your invoices are delayed? If you had a streamlined system that links the tickets to the order and requires the tickets to be entered at the point of generation, you would get the following advantages:

When this ticket collection is tied to your dispatching system, it is much easier to know when a job has been completed. Think of how much work is involved for the dispatcher when there are 20 trucks on an order and 40,000 tons are needed to complete the job. How do you keep up with this in real-time if you don’t have a ticketing system integrated with your dispatching system?

If the ticketing system is tied to the dispatching system and the drivers enter the tickets upon loading, the dispatcher will know exactly when the correct amount has been loaded. This prevents your coming up short or ending up with trucks loaded with product you can’t deliver.

If the drivers enter the ticket amount and take a picture of the ticket to load it into the system, you won’t be overrun by paper tickets in your office. When a client calls in requesting proof of a load, you can send them a digital version which was found in seconds by searching for the order.

If you get an order from a new customer that you have not done a credit check on, put them in a COD status. If the COD customer is using a credit card, pre-authorizing before delivery reduces the chance of them failing to pay.

Preventive maintenance can reduce your fleet costs. It is less expensive to replace the $5 part in the shop than it is to tow a broken-down truck to the shop. In addition to having to pay for towing and repair, the truck is out of service and not producing income. A well-maintained truck will have a longer serviceable life.

Do you have a written preventive maintenance plan in place? Can you see at a glance which vehicles have reached the mileage, date, or hours that they are supposed to have a PM done? If not, you may want to consider getting a vehicle maintenance system to help you keep your PM plan on track.

If you get a cloud-based vehicle maintenance system that ties into a telematics platform, the mileage and PM warnings can be generated automatically. This is a great way to make sure all your trucks are maintained properly. While a good vehicle maintenance system will typically cost $2 or $3 per truck, it takes a lot less effort to implement than a manual system. Manual systems are often neglected, and PMs are frequently overdue.

Several of the telematics platforms have a simple preventive maintenance warning system built-in. If you are on a budget and want the benefits of a PM program and the benefits of a telematics platform, be sure to choose a system with this capability.

While preventive maintenance is a good start, it is typically based on manufacturer suggested maintenance frequencies. A dump truck or cement mixer that spends a lot of time in the vicinity of dusty aggregate and rough terrain requires more maintenance than a truck running down the interstate for most of the day.

Because of these differences, you should change preventive maintenance frequency to account for your environment. While this is a good start, there is still some variation between how the trucks are used daily. There is also a difference in how parts wear due to driver behavior differences. Brakes are a good example of this. Some drivers go through brakes faster than others.

So how do you account for these usage and driver differences and build them into your PM plan? In short, you can’t. Instead, there are 2 approaches you can take. First, you can do inspections and take measurements at more frequent intervals than the suggested maintenance interval. Using this measurement, you can tell how much the item has changed or worn during that period and can use that as an estimate for when the maintenance is due.

The second approach is to use technology. You can install a telematics device into the truck. This device can send engine diagnostics back to the server which then processes the data. After the data is processed, maintenance can review the alerts and run reports to see which trucks need to be looked at.

In addition to the warnings sent by the system, you may also view patterns in the data from multiple indicators that suggests a problem is coming even though an individual indicator may not have reached a limit. Over time, these systems will get smarter and offer even better indications of upcoming issues based on multiple variables.

The above 2 approaches to predictive maintenance should be used in combination. The 2 approaches tend to focus on different metrics and components. The inspection approach is typically used for components that are not available to the on-board diagnostics. Values such as temperatures, pressures, and other sensor values available to telematics are easier to analyze, track, and view.

Do you have drivers who believe that they can thump a tire and tell if it is set to the correct pressure? They are wasting their time and won’t be much more accurate than banging on the oil pan to tell if the oil level is good.

Proper tire inflation is important as it impacts profit in several ways. The following are several benefits of properly inflated tires. The costs below assume the truck is running 1 shift per day, 5 days per week.

Reduces fuel cost

Every 10% reduction in pressure results in approximately 1% reduction in fuel. That means that a truck travelling with tires 10 psi low on average is wasting $200/year in fuel alone. According to an FMCSA study, only 44% of truck tires were within 5 psi of their target pressure. 7% were off by more than 20 psi.

Reduces tire wear and uneven tire wear

Underinflated tires increase tire wear-related costs to approximately 12% which on average works out to $200/year for a typical dump truck operation.

Reduces tire blowouts

In the FMCSA 2006 study, there was on average, 1 blowout per 18 tires in a year. Add the cost of a service call and the lost production to determine this cost for you.

Reduces accidents

Under-inflated tires can change the handling and increase the braking distance, increasing the chance of an accident.

Reduces legal costs

Tire blowouts and accidents resulting from tire issues can get very expensive when they result in legal battles.

Now that you have seen the direct and indirect expenses associated with improperly inflated tires, you can decide what approach to use to address the issue.

1. Require drivers to use a pressure gauge to measure the tire pressures as part of their DVIR

One downside to this approach is the time required to measure the pressure of each tire. On a triaxle dump truck with 10 tires, it will take between 10 and 15 minutes for the driver to measure the pressure. At 5 inspections a week for 52 weeks, this cost works out to $780/year if drivers are paid $15/hour.

Another disadvantage of this approach is that not all drivers will consistently do these checks.

2. Get a tire pressure monitoring system (TPMS) that displays in the cab

These systems cost $700 to $1,000 one time for a triaxle dump truck. While this system only takes a minute for the driver to verify that the pressures are correct, the driver still must take action to fill the tires or to report it to maintenance to correct.

3. Get a tire pressure monitoring system that reports via a telematics system

These systems cost approximately $1,000 one time for a triaxle dump truck. There may also be an added cost to pass this information through the telematics system. For example, if you use a Valor system with Geotab, the added cost will be around $60/year for a truck.

In this last approach, the telematics system can send emails and give reports of tire pressures. Automated checks reduce the time and money people spend managing the tire pressure process. While the first-year costs may be the same or slightly higher than the other 2 options, it has the greatest long-term savings. This approach also results in the most consistent tire pressures.

For more information regarding TPMS, visit our article on evaluating Tire Pressure Monitoring Systems.

In some of the above, we talked about how improved truck maintenance can reduce the chance of an accident. However, the major component that needs to be addressed is the human element. Certain drivers exhibit behaviors that are more likely to result in an accident. The top 3 of these are:

Other behaviors may result in excessive wear on vehicle components or wasting of fuel. We have all seen some driver that likes to eat lunch in the cab while enjoying the air conditioning for an hour or more. Then some drivers accelerate quickly and others like to ride the brakes or not use turn signals.

There are systems that can monitor for these behaviors and warn the driver when they are exhibiting them. These systems also generate reports for management to use as a scorecard for the drivers to ensure that they are improving. If they are not improving, it is because they are not following the warnings and should have corrective action initiated against them by their managers.

Several of the popular telematics products include this functionality, so you don’t have to get a separate system from the one you are using for GPS and engine diagnostics. It is more affordable to find one system that covers the range of needs mentioned in this article. Geotab and Samsara are two telematics platforms with great safety monitoring and alerts. Both also support cameras.

Improving truck utilization starts with tracking any time a truck is out of service during the workday. This can be as simple as creating an Excel spreadsheet with 3 columns:

Periodically, you will analyze the data and generate a list of causes sorted by the highest number to the least. The easiest way to start is to look at those reasons near the top of the list that can be easily prevented and put a process in place to fix them. For example, if the truck was out of service because preventive maintenance was done on it, an easy fix would be to make sure all preventive maintenance is done outside the workday.

The following list includes some typical items that may be on your list:

For some of these causes, a way to reduce them may not be obvious and may require some out of the box thinking. Don’t limit your thinking to “this is the way the industry has always done it” and don’t accept that there is nothing that can be done to improve the situation.

There are other less obvious ways that utilization can be impacted. In this other category of utilization detractors, the truck is technically in use, but it is not being as productively as it could be. These items won’t be in the list you created above. A few items that fall into this category are:

All the things in this list can be improved and automatically tracked with good dispatching and vehicle maintenance software tied to a telematics platform. Dump Truck Dispatcher has built integrations with Geotab and Samsara. In my opinion, these are the two best telematics/GPS systems.

Dispatching is a difficult job. Having to replace a dispatcher is an expensive proposition when you factor in the job search, the training time, and the inefficiencies caused by beginner mistakes.

There are a lot of communications and chaos in the typical dispatch room. The dispatcher has to coordinate with salespeople, customers, and drivers and keep everything flowing smoothly. He will typically be working across a couple of computers, have a phone in one hand, and a radio in the other. There is often somebody on hold on the phone as well. There might even be a person or 2 in the office trying to talk with him.

It is no wonder that dispatchers burn out so quickly and move on to another job. Then the process of training a new person starts. It takes a while for this new dispatcher to come up to speed. During this ramp-up time others are often taken from their job to help.

If you could remove some of the many communications and reduce the stress level of the dispatchers, you would go a long way toward retaining them. Software to improve the situation could:

As you can see in the above list, most of the functionality specified cuts down on the communications being done by the dispatcher. Instead, they can use the software to get their answers, so they aren’t trying to juggle the phones and radios as often. Leveraging technology allows multiple communications to be sent at once and for the incoming messages to be queued up until the dispatcher has the time to check the messages.

A system that does this might even make your dispatcher love their job again.

Telematics offers many benefits. In several of the above tips, I detailed how it can be useful in regards to maintenance, safety, and fleet efficiency. Not mentioned above was the use of telematics for GPS services. This allows you to see where trucks are, so you can efficiently dispatch them or to see who might not be where they are expected to be.

Many telematics platforms also provide a means for dispatching and messaging a driver. This functionality generally requires you to have an added device such as a tablet, or phone to send and receive the dispatches and messages. Using a device in this way cuts down on much of the traffic coming in via radios and telephones. It also means the dispatcher doesn’t have to have everything in their brain as they can always look it up on the system.

One downside to the dispatching functionality in these telematics systems is that it is not tied to the plan or schedule and still requires a dispatcher to control every delivery or stop. We are continually improving our connections to telematics systems and would love to hear of some of your needs so that we can be sure to build it to meet your needs. If you would be willing to share your advice, please reach out to me via the chat window to the right.

You may have noticed that many of the above options implement technology to improve your profits. If you choose the correct technology solution, you may be able to accomplish several of the above at the same time. For example, if you choose the correct telematics system, you may be able to use it to improve your maintenance operations, driver behavior, and dispatching. Using software like Dump Truck Dispatcher to provide the business functionality while integrating with your telematics and accounting system, adds even more benefits.

If you are in the dump truck hauling, concrete, or asphalt industries, and would be interested in a free 30-minute consultation about which technologies might be most appropriate for you please schedule a demo via one of the big red demo buttons.

Do you use lease haulers or sub-contractors? How do you get them to sign your contract, and provide company and insurance information? If you do this like most companies, you ...

What is the difference between the most successful hauling companies that are growing and the typical hauling company? The most successful companies have excellent processes that support their ability to provide excellent service to their customers. They have ...

Most aggregate hauling companies are not taking advantage of technology to improve their customer service. If your company implements these 5 ideas, you will stand out from the other hauling companies. This advantage can be marketed and will result in happier customers that do more business with you.